Cranks

Page Navigation

GENERAL OVERVIEW

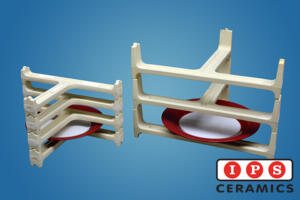

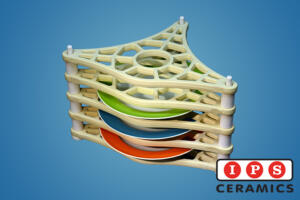

IPS Ceramics’ T-Cranks, Y-Cranks and Web Cranks are used to support plates, flatware and holloware during decoration and glost firing. Easily stacked to maximise kiln-fill, our T-Cranks, Y-Cranks and Web Cranks contact the ware at only certain points of the foot, minimising the risk of plucking or sticking.

T-Cranks and Y-Cranks are easier to load and unload without separating the stack. The Web Cranks can be lighter weight and allow for better heat distribution.

Designed to provide maximum support using minimal material, IPS Ceramics’ cordierite cranks provide a low cost, low weight, low energy solution to supporting ware through lower temperature firings.

TECHNICAL INFORMATION

| T-, Y- and Web Cranks | |||||

| General Information | |||||

| Type | Standard | Glaze Resistant | Cast (Standard) | Cast (Enhanced) | Cast (Thermal Shock Resistant) |

| Max Usage Temp. | 1300 °C / 2372 °F | 1250 °C / 2282 °F | 1250 °C / 2282 °F | 1250 °C / 2282 °F | 1250 °C / 2282 °F |

| Typical Physical Properties | |||||

| Bulk Density | 1.85 g/cm³ | 2.20 g/cm³ | 1.90 g/cm³ | 1.90 g/cm³ | 1.80 g/cm³ |

| Apparent Porosity | 28 % | 25 % | 27 % | 29 % | 32 % |

| MoR @ 20°C | 15 MPa | 14 MPa | 15 MPa | 30 MPa | 16 MPa |

| MoR @ 1250°C | 13 MPa | 12 MPa | 15 MPa | 25 MPa | 15 MPa |

| CTE 20 – 1000 °C | 2.4 x10-6/K | 2.4 x10-6/K | 2.5 x10-6/K | 2.6 x10-6/K | 1.8 x10-6/K |

| Specific Heat @ 20°C | 1.0 kJ/kg.K | 1.2 kJ/kg.K | 1.0 kJ/kg.K | 1.0 kJ/kg.K | 1.0 kJ/kg.K |

| Typical Chemical Analysis | |||||

| Al2O3 | 37 % | 25 % | 42 % | 38 % | 44 % |

| SiO2 | 50 % | 45 % | 48 % | 45 % | 48 % |

| MgO | 8 % | 8.5 % | 7.5 % | 8 % | 10 % |

All figures are typical figures determined using laboratory test pieces and might not always be an accurate representation of production item.

PHOTO GALLERY

DOWNLOADS

- IPS Ceramics Cordierite Datasheet (PDF)

- IPS Ceramics Catalogue (PDF)

- IPS Ceramics User Guide to Cordierite and Mullite Kiln Furniture (PDF)

RELATED PRODUCTS

|

|

|

| TFS Setters | Pin Cranks | Profile Setters |